Precautions for Construction Workers in Summer

Construction Job Site Precautions for Warm Weather

Issues with extreme weather can rise major concerns for employee safety. And as we are getting closer to the summer and temperatures start to rise, a bigger concern arises.

According to the Occupational Safety and Health Administration, most heat-related job site deaths occur in the first three days of work, and half happen on the first day.

Workers need time to get adapted to hot weather, particularly any employees who haven’t worked outdoors recently.

Below are some tips on how to protect your workers from suffering a heat stroke in a work zone:

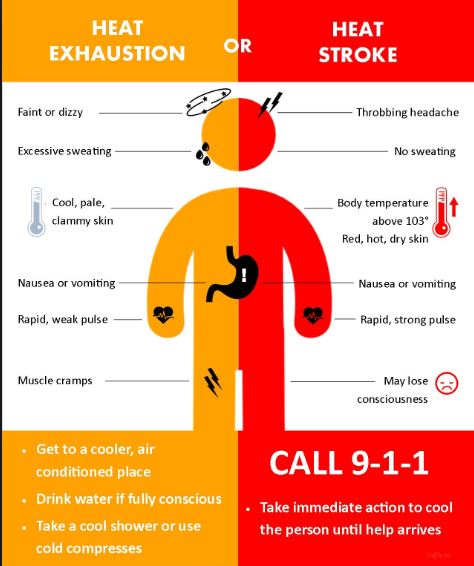

- Train all workers to recognize and treat the signs of heat stress. Be sure all workers know who has been trained to provide first aid. Also train supervisors to detect early signs of heat-related illness and permit

workers to interrupt their work if they become extremely uncomfortable. They should know whom to notify in case of a heat emergency, such as a supervisor or even 911.

workers to interrupt their work if they become extremely uncomfortable. They should know whom to notify in case of a heat emergency, such as a supervisor or even 911. - Consider a worker’s physical condition when determining fitness to work in hot environments. Taking certain medications, lack of conditioning, obesity, pregnancy, and inadequate rest can increase susceptibility to heat stress.

- Help workers adjust to the heat by assigning a lighter workload and longer rest periods for the first 5 to 7 days of intense heat. This process needs to start all over again when a worker returns from vacation or absence from the job.

- Workers should drink at least a cup of water every 20 minutes and be trained to recognize the signs of heat illness — such as dizziness, nausea, confusion and an accelerated heartbeat — in themselves and others.

- Avoid alcohol, coffee, tea, and caffeinated soft drinks that dehydrate the body.

- Encourage workers to wear lightweight, light-colored, loose-fitting clothing.

- Use general ventilation and spot cooling at points of high heat production.

- Alternate work and rest periods, with rest periods in a cooler area. Shorter, more frequent work-rest cycles are best. Schedule heavy work for cooler times of the day and use appropriate protective clothing.

- Monitor temperatures, humidity, and workers’ responses to heat at least hourly.

- Employers should provide air-conditioned, or at least shaded, areas and allow for frequent water and rest breaks.

But you also need to take in consideration that worker safety isn’t the only warm-weather worry construction companies have. Materials and equipment can also be negatively affected by heat.

Below are some tips on how to better use your equipment during these hot days:

Below are some tips on how to better use your equipment during these hot days:

- If the project is in a location where summers are dry, dust can get into the machinery, meaning more cleaning and additional filter changes for job site vehicles and heavy equipment. A stepped-up maintenance program will need to take place to prevent costly damage to equipment or malfunctions that could put workers at risk.

- As a worker can suffer from heat stroke, equipment can overheat in the summer as well. So, it is a good idea to do regular checks on them for proper coolant levels, as well as ensuring hydraulics systems are maintained with adequate levels of oil. Companies should make clear to operators that they shouldn’t stress the equipment with heavier-than-normal loads or particularly demanding operations when it’s hot out.

- Elasticity of seals can be damaged by heat and exposure to UV rays, so companies should take care to protect those expensive parts from exposure — for instance, by garaging or parking a vehicle under shade when not in use and scheduling operations for times when the temperature and sun exposure aren’t at their highest.

- Material performance can also suffer in hot weather, especially brick mortar. While mortar needs moderate temperatures to set properly, too much dry heat can suck the moisture out of it, causing it to settle too fast, before it can bond to the brick. This can result in a weaker masonry unit that leaks or experiences crumbling of mortar down the road. Solution: Mix smaller amounts and use them up fast. Keep the mortar covered.

- Concrete curing can be hindered by extreme heat. The Portland Cement Associations recommends measures such as shading, using fogging to maintain moisture in the air around the pour and even moving the pour to a time when temperatures are cooler.

- As the temperature rises starting in spring, construction season heats up, which is great for the bottom line. With a little planning, contractors can keep employees safe, equipment online and productivity humming.

NEED MORE INFORMATION? IQV CONSTRUCTION & ROOFING is here to help!

call us at 408-638-5500 or request a proposal online.